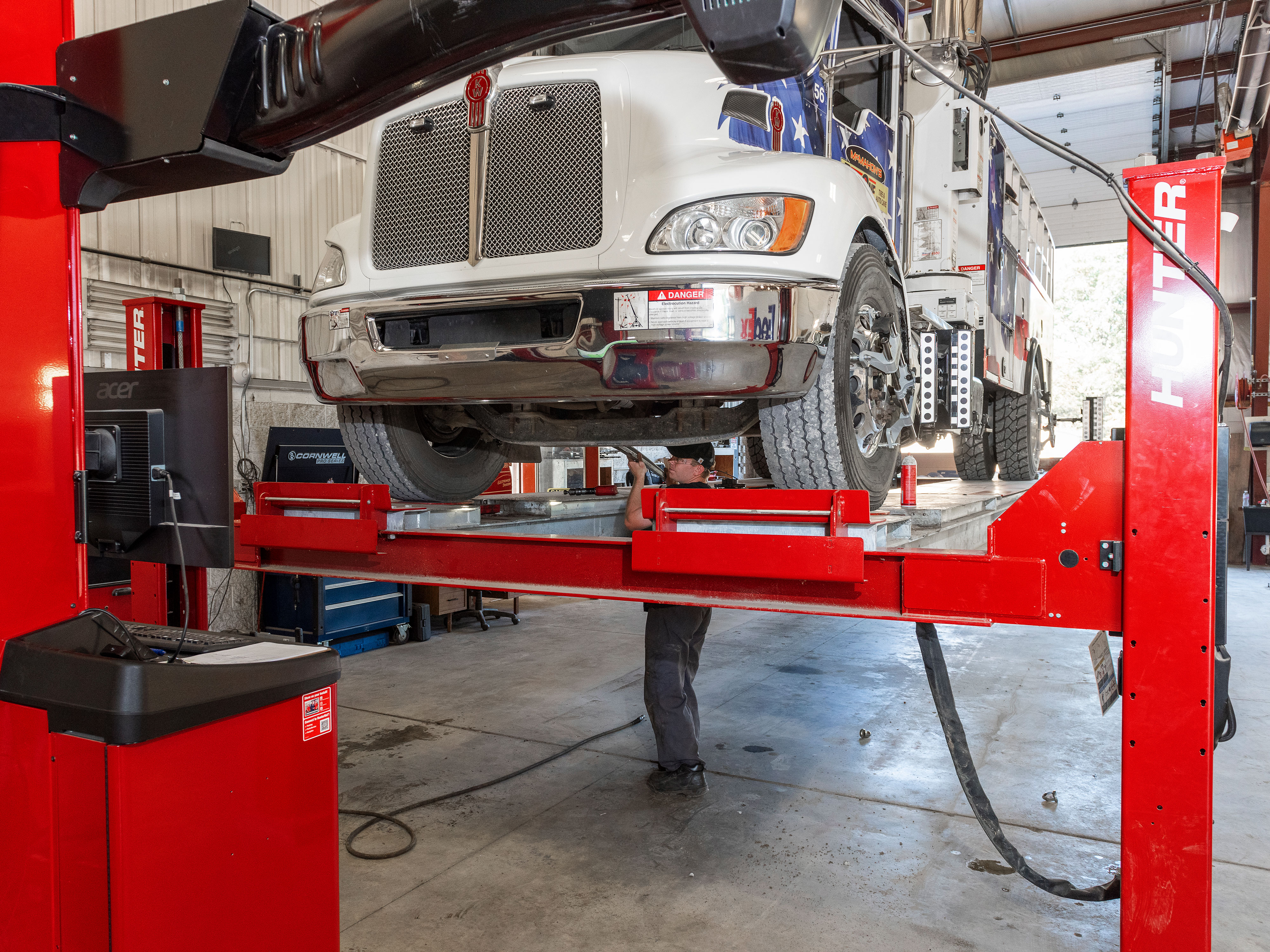

Move the aligner for use in any bay, on the floor or a lift, with adjustable camera beam.

Alignment System

Hunter HawkEye® XL

Fast and highly-capable heavy-duty alignment machine. Hunter's patented camera technology excels where it matters most.

HawkEye® XL

/

Big or small, align them all.

Three-dimensional XL targets are durable, low maintenance, and non-electronic

High-definition cameras are accurate, precise, and offer extra-long-range sight

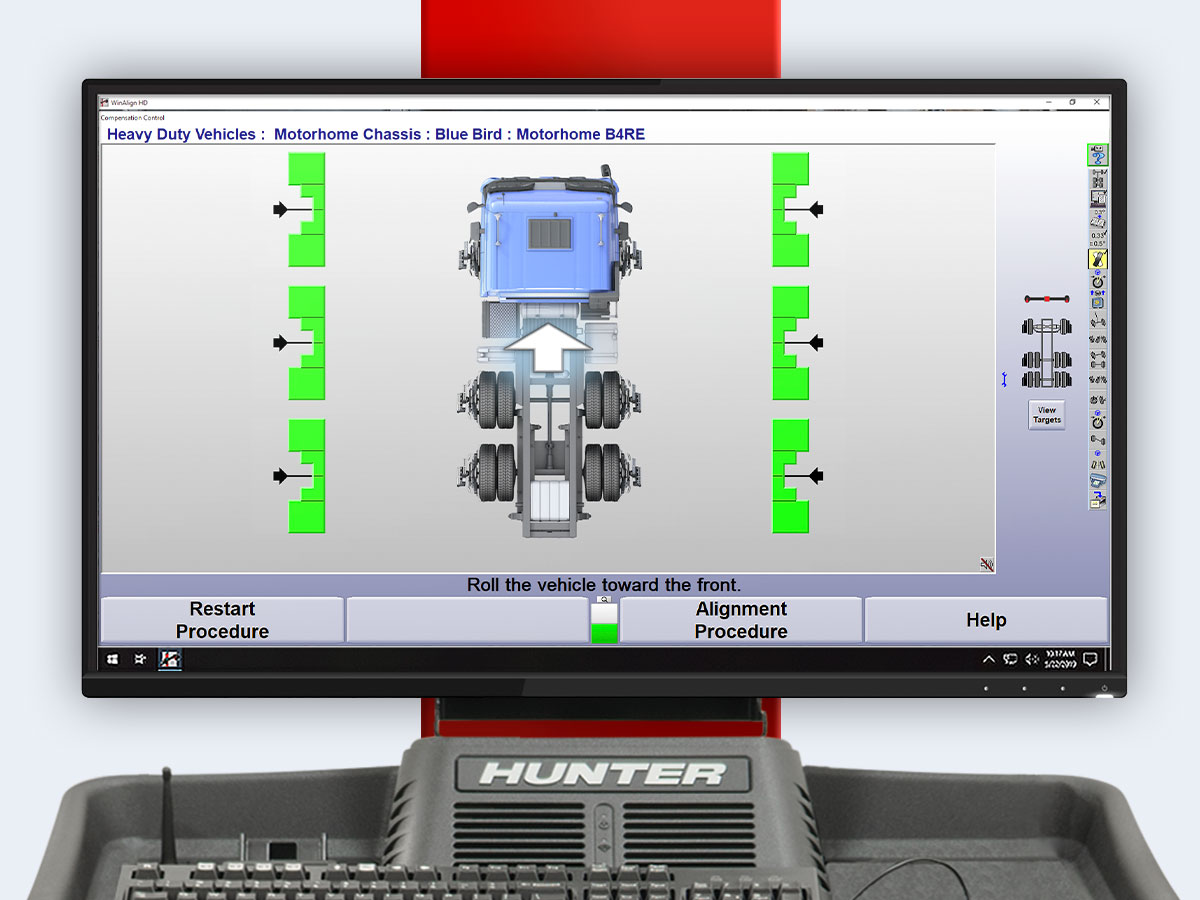

Capture all measurements in a single rolling compensation

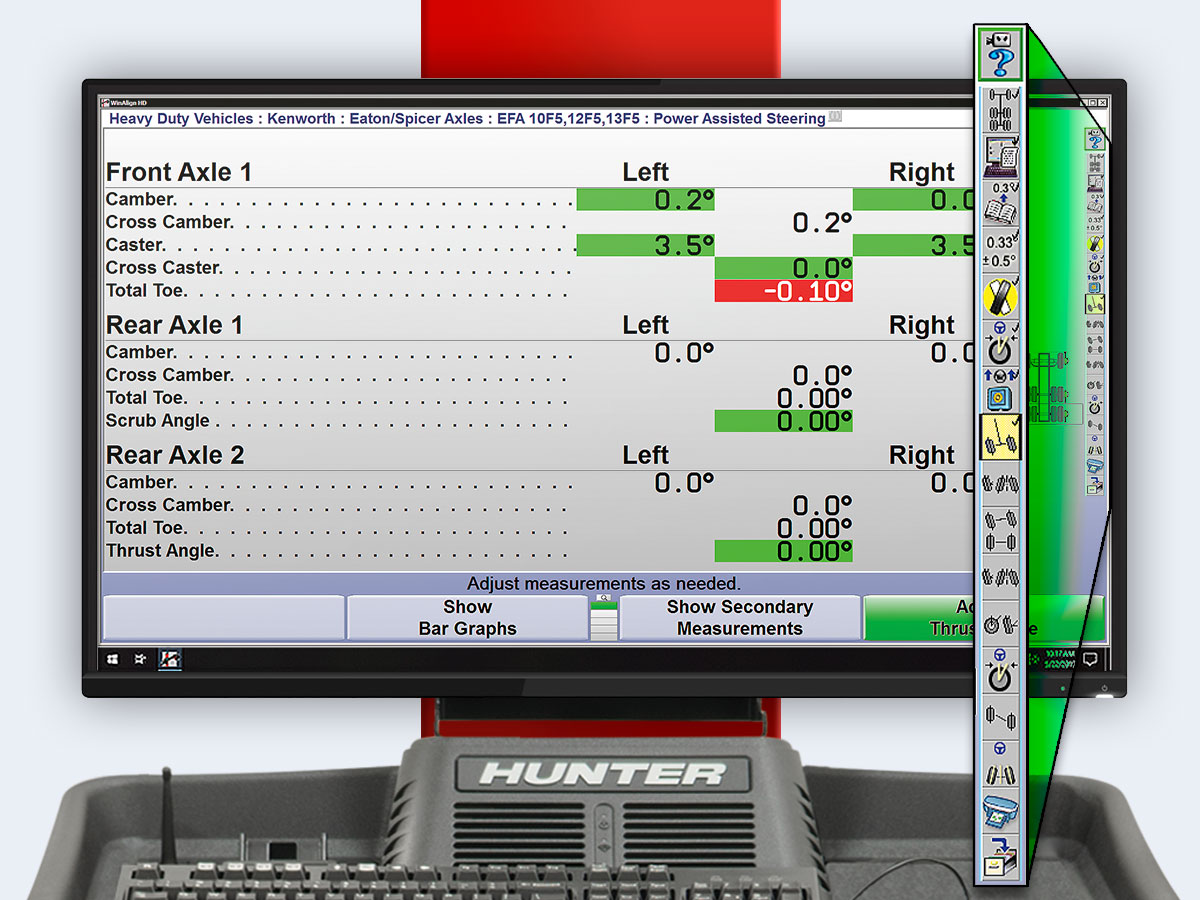

See live alignment readings from three axles at once

Perform wheel alignments on any surface, in any bay

Fully Integrated Alignment rack integration streamlines processes

HunterNet® connectivity to see and manage your performance

Hunter's industry-standard vision technology built for commercial vehicles

Fast and easy to use

Extra large vehicle coverage

Live measurements

High uptime, low cost of ownership

Big or small, align them all with HawkEye XL

Watch the HawkEye XL Hype Video.

HawkEye® XL commercial aligner helps Prime Inc. maintain its “nonstop” pace

The new HawkEye® XL commercial aligner was designed for techs like Vernon and commercial shops like Prime Inc. in Springfield, MO in mind.

HawkEye XL® Alignment System: Beginner's Operation Guide

Field training manager Miles Dierker describes the proper techniques for the smoothest and most efficient operation of the Hawkeye XL®, powered by WinAlign® software.

Fast and highly-capable HawkEye® XL heavy-duty alignment machine

The all-new HawkEye® XL alignment system from Hunter Engineering® features three-dimensional XL targets, high-definition cameras, and three-axle live alignment readings from a single rolling compensation on any surface or any bay.

Designed & Built in the USA

For 75 years, Hunter Engineering Company® has been designing and building automotive service equipment in the USA.

Ready for whatever comes through your door

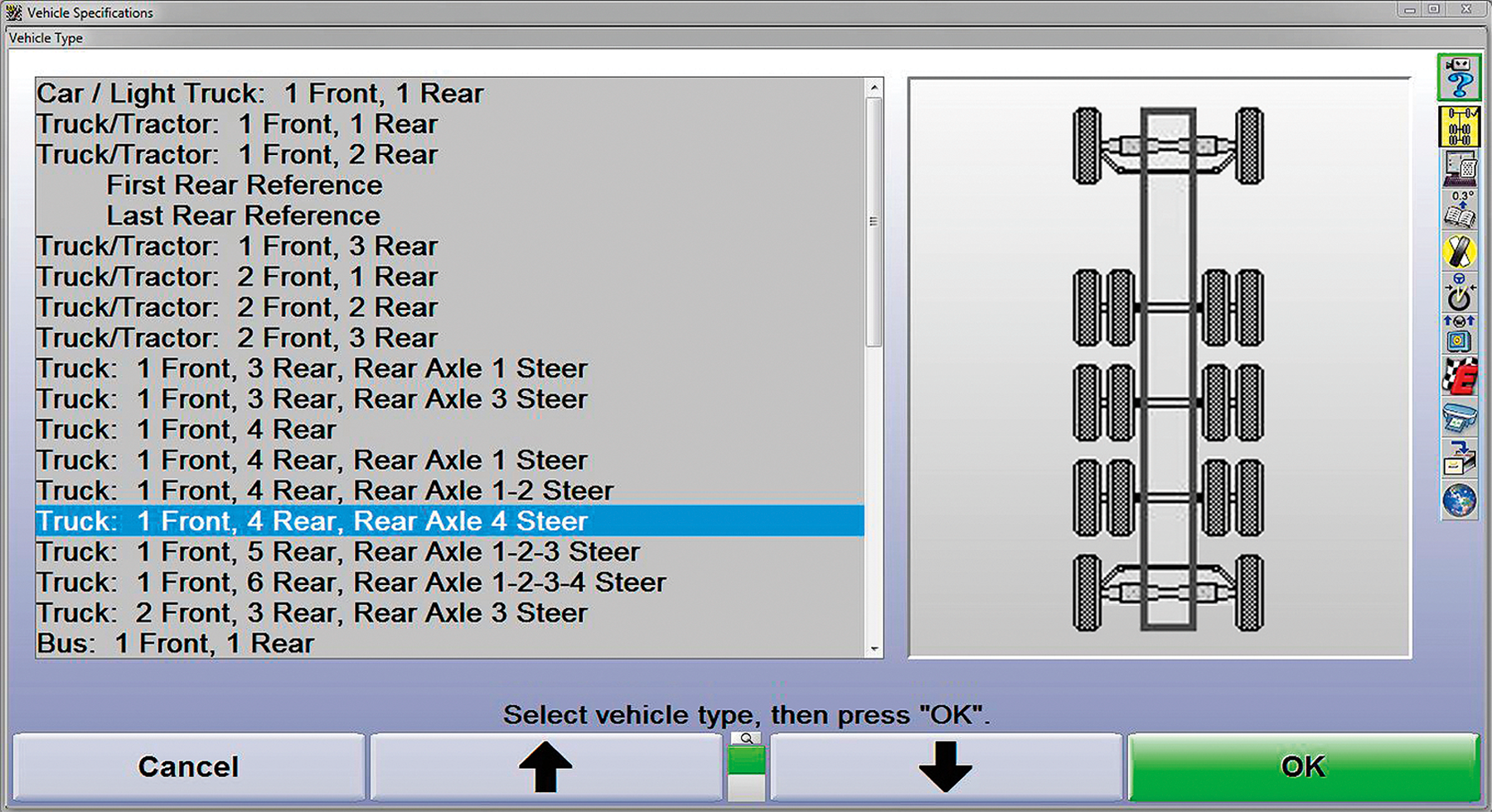

Align a wide range of commercial vehicles from semi-truck tractors, trailers, big rigs, buses, box trucks, and even passenger vehicles.

Truck and bus

Trailer

Medium-duty

Light-duty

Calculate your payoff and profits

HawkEye® XL features

Alignments in any bay

Multi-Axle Readings

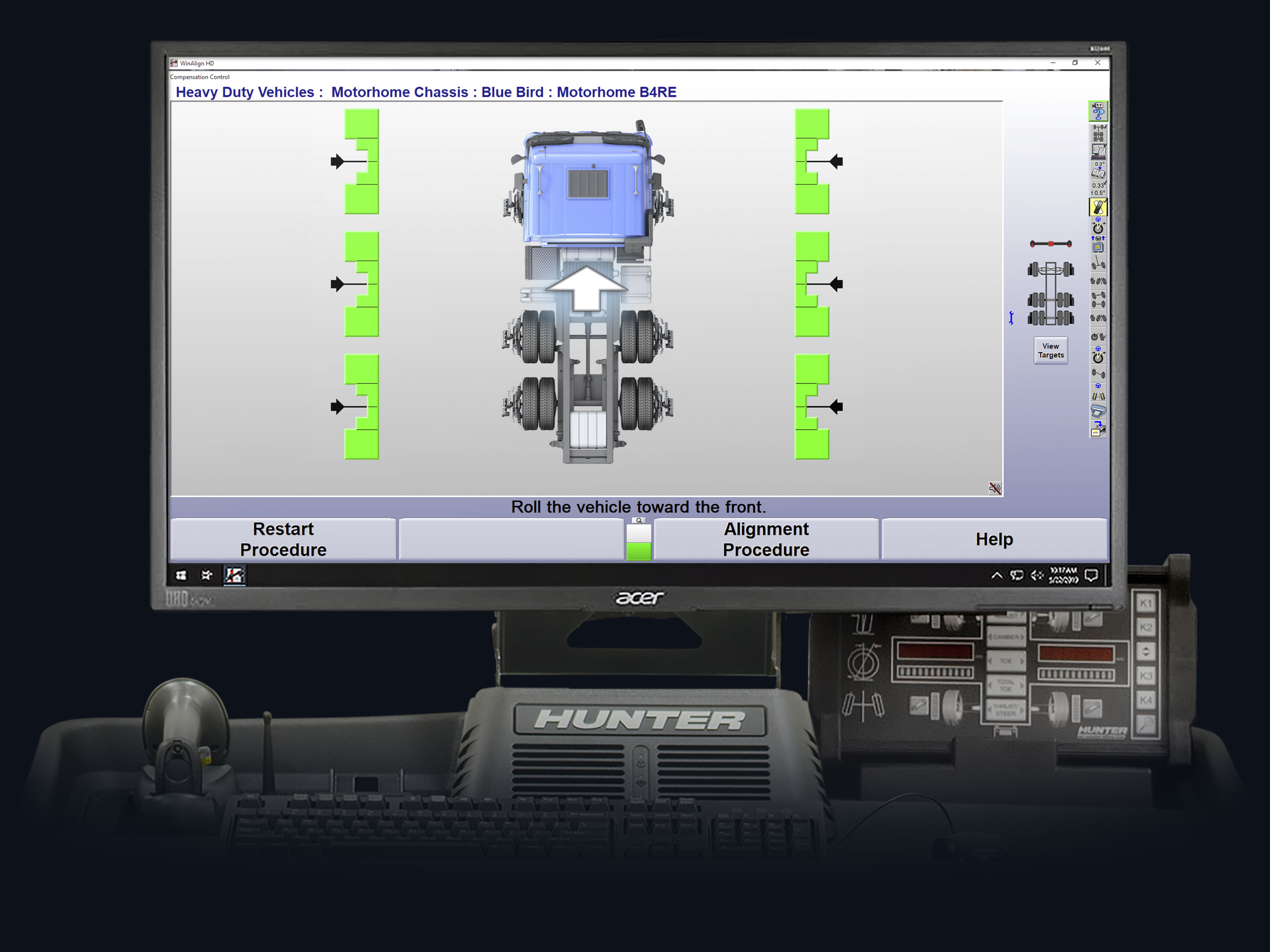

See live alignment readings from three axles at one time with guided procedures.

XL Targets

Hunter's patented 3D targets offer extreme durability, low maintenance, and no electronics at the wheel.

Trailer alignment

Long-range cameras easily see targets on 53-foot trailers. Align using optional kingpin adaptor.

Truck Pusher

Optional

Effortlessly move vehicle for rolling comp with rechargeable battery-powered pusher.

High-definition cameras

Extra-long range, high-resolution cameras precisely monitor each wheel in a 3D space to provide pinpoint-accurate measurements.

Focused on the technician

Hunter's HawkEye® XL is built to make your technician's work easier.

Ease-of-use

Durable, low maintenance, and non-electronic

Speed and efficiency

Designed for less hassle and more accuracy

Training assistance

Guided alignment procedures walk you through each step

Service support

Local field teams are on-call to minimize downtimes

Handle any vehicle

HawkEye® XL is built to align vehicles big and small, including light-duty vehicles, medium-duty fleet vehicles, heavy-duty trucks and agricultural vehicles.

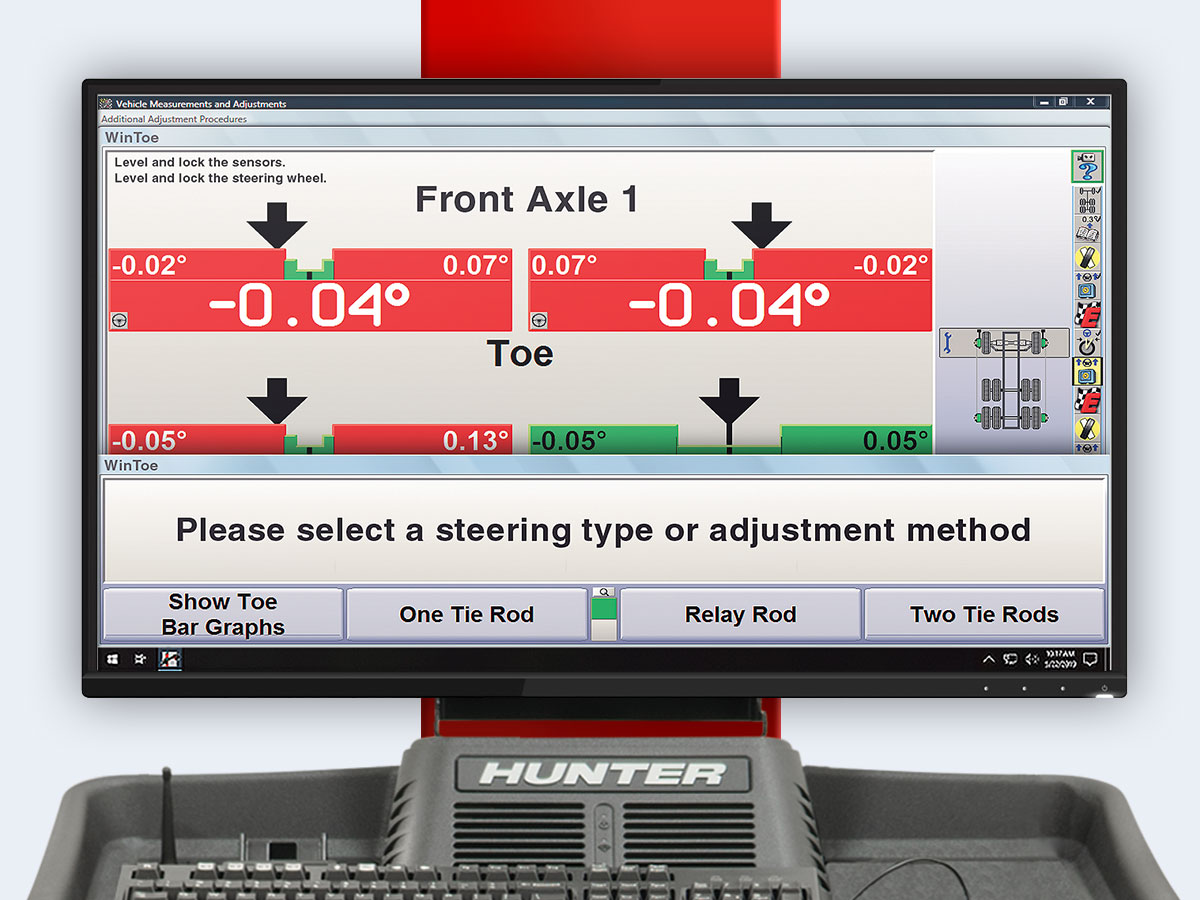

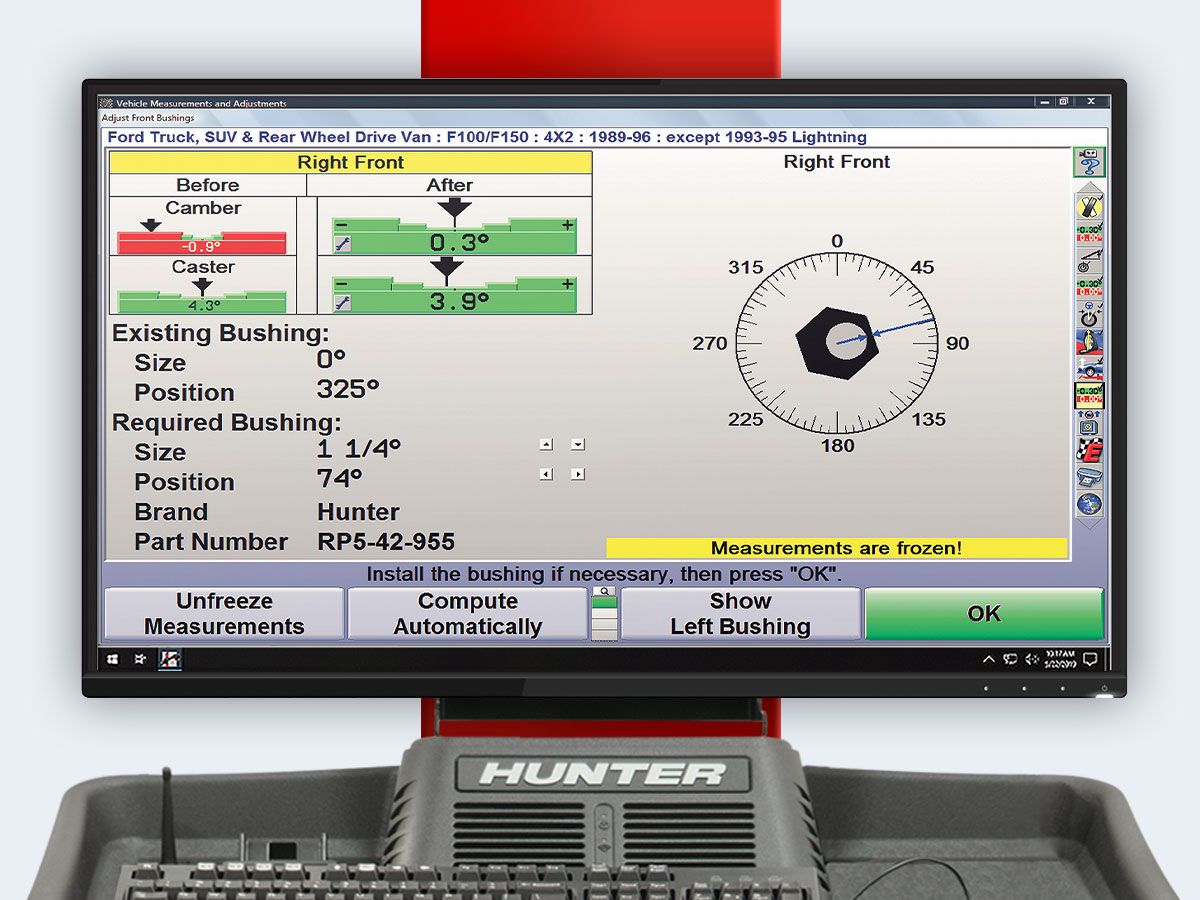

Measure and align all axles using Hunter's award-winning WinAlign® HD software

Guided procedures

Vehicle-specific procedures guide the operator with step-by-step instructions.

Patented power tools

Procedures designed so you can complete the work accurately the first time, every time.

Light-duty vehicles

Additional features included for servicing light-duty vehicles.

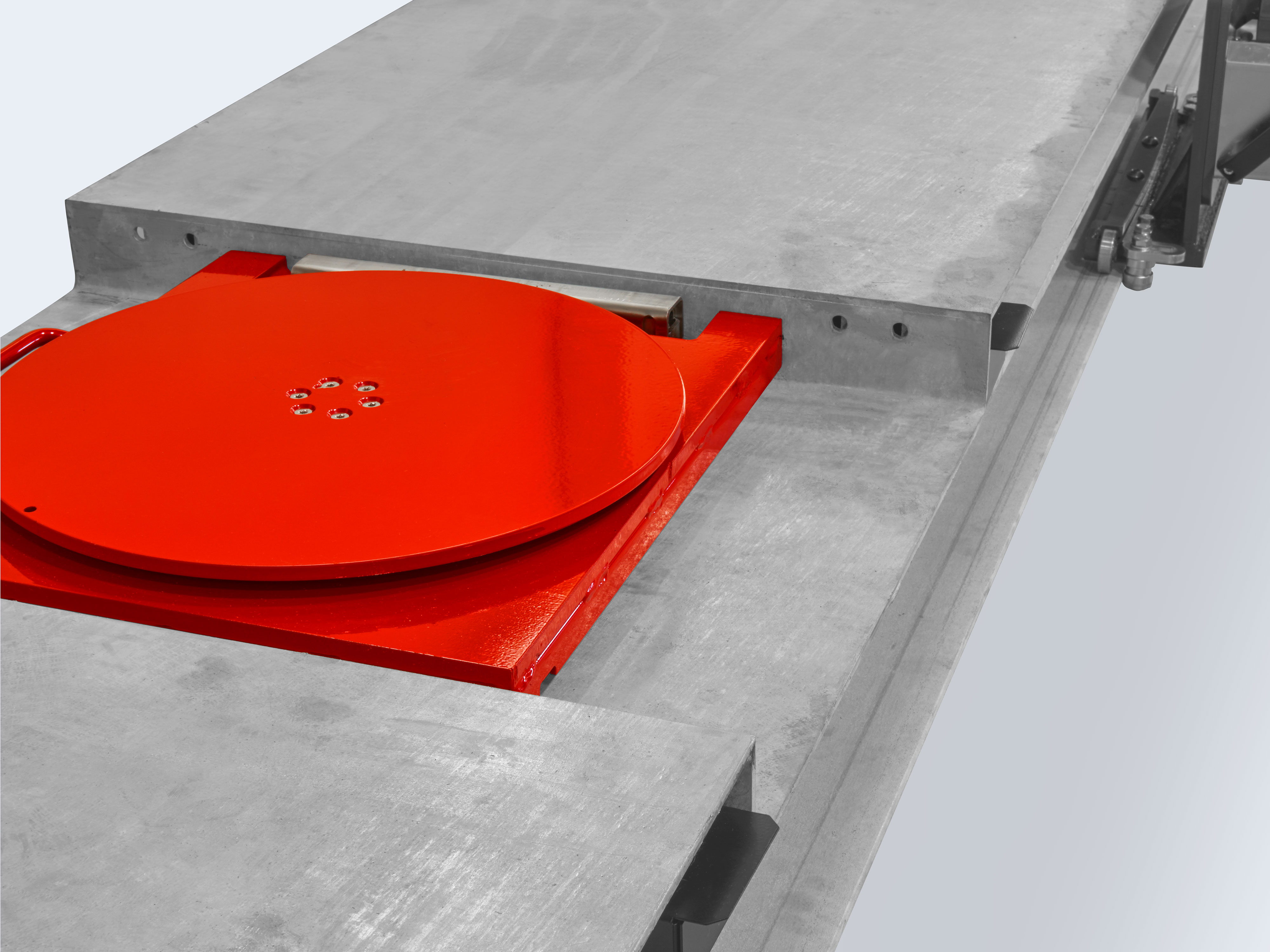

Streamline the process with Fully Integrated Alignment (FIA)

Requires FIA-capable Hunter lift or turnplates

1 trip

To the aligner console

0 jacking axles

Required

81 steps

Total in the process

4 minutes

To get alignment readings

WinAlign® console

Communicates directly with lift to automatically operate turnplates and slip plates.

Heavy-Duty Four-Post lift console

Raising the vehicle triggers the sensors to look for wheel targets.

PowerSlide® system

Slip plates and turnplates automatically lock and unlock at the appropriate times.

Equip your shop for efficient alignments

Hunter's Heavy-Duty Four-Post semi and truck lift features a 158,757 kg. lifting capacity, 7,620 mm. alignment wheelbase capability, galvanized runways and turnplate pockets and slipplates for servicing standard vehicles. It can be equipped with optional Powerslide and FIA functions that connect it to the aligner to streamline your alignment process.

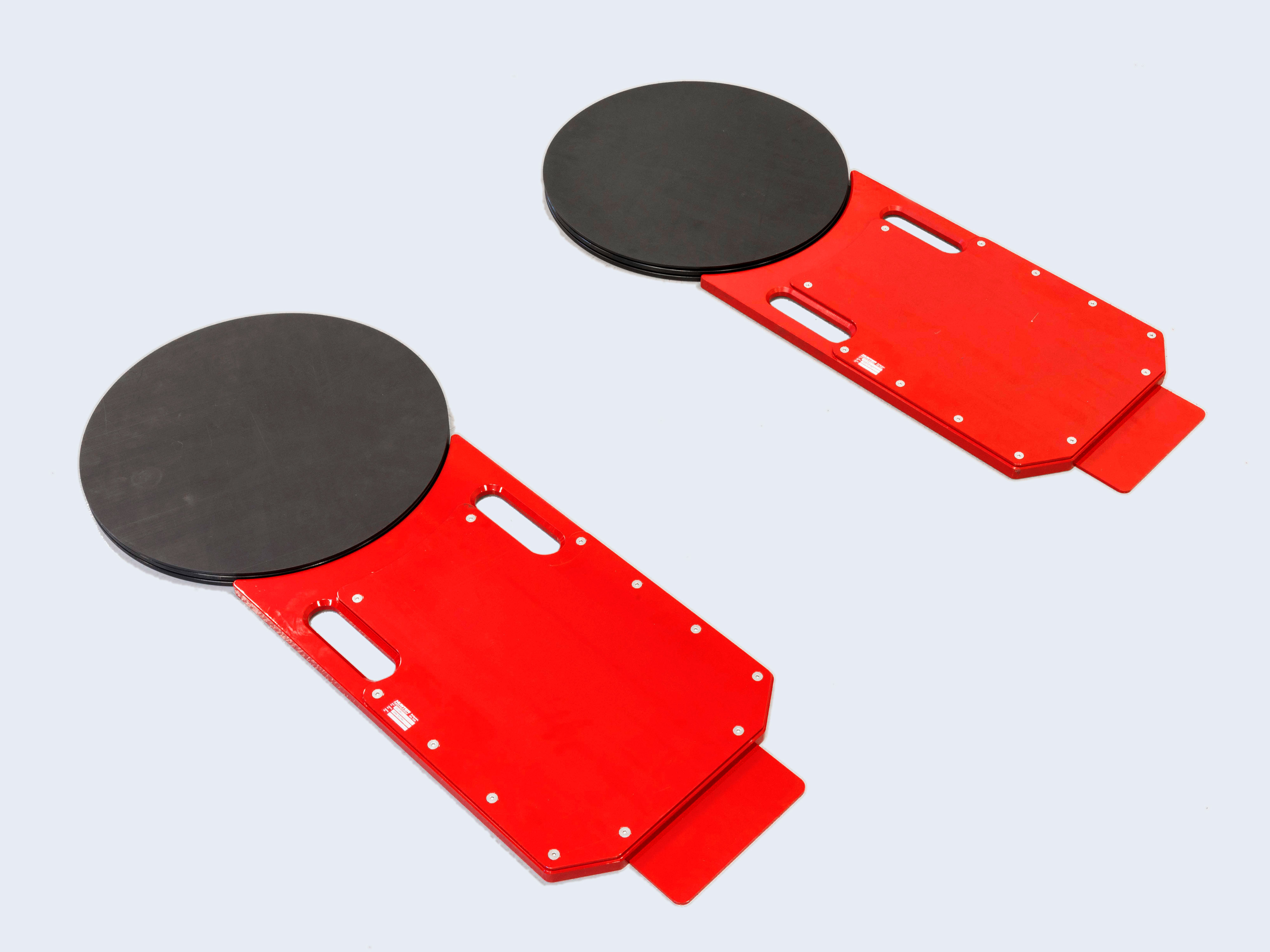

Turnplate options for floor or other racks

Other options to expand your capabilities

Convenient Accessibility

- Rolling Storage Cart - Hang targets for quick access.

- Secondary Console Kit - Provide better visibility and control. Mounts to cart shown.

Mini Self-Centering Clamps

Mount to hub center of front rims. (set of 2)

Trailer Gauge

Mounts to the kingpin for trailer alignments.

Remote Indicator

Maintain control while making adjustments.

Wide-Angle Targets

Easily and accurately measure max steer.

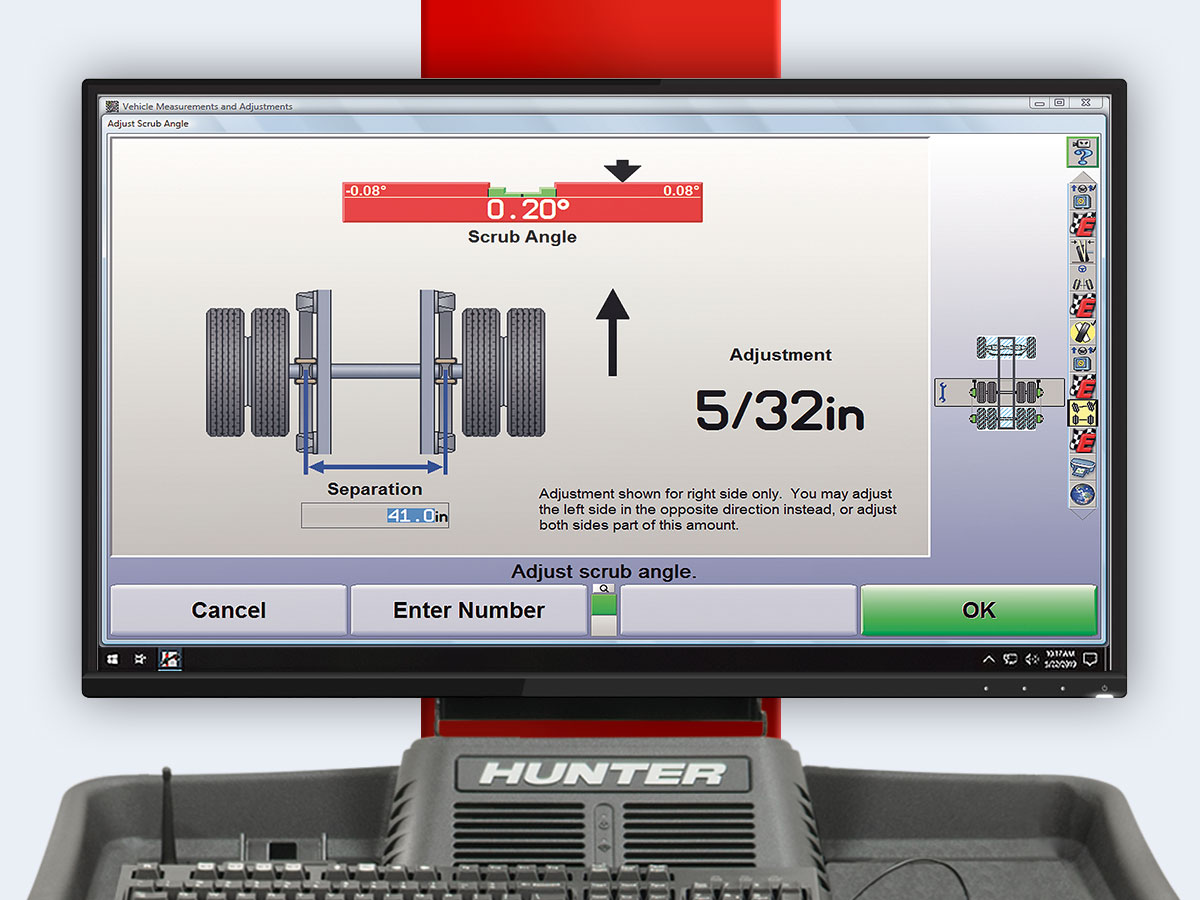

Unlock profit potential with Quick Check® Commercial unmanned inspection

Inspect for camber, total toe, scrub and tire wear on every truck, axle and tire that comes into your shop with no technician required. Keep your equipment producing with a steady stream of high-margin alignments.

Hunter's patented camera technology excels where it matters most.

Want to see it in action?

Send a message to your local Hunter heavy-duty business consultant to schedule a free on-site demo.

Connect your equipment to your business

- Maximize your shop's performance

- Simplify customer discussions with selling tools

- View extensive undercar information

Monitor Trends

Get a high-level overview of your alignment machine usage trends.

Receive daily reports

Setup to receive daily Push Reports to keep your goals and performance in check.

Recall Past Results

View previously serviced vehicles and recall printouts.

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.